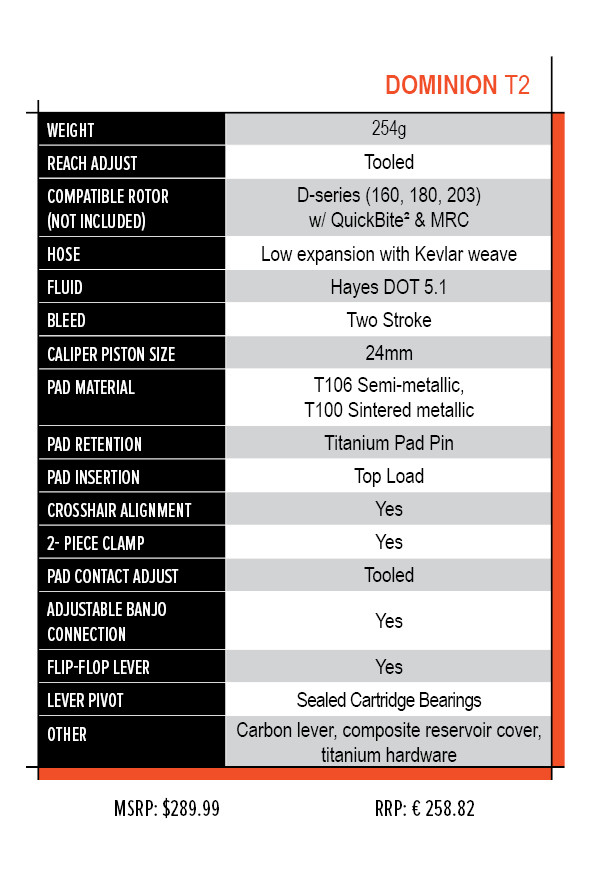

The best just got better. The limited-edition Hayes Dominion T2 packs the power, sensitivity, and reliability the Dominion family is known for into its lightest chassis yet. Featuring a Reynolds designed and in-house produced carbon-fiber lever, titanium hardware, composite reservoir cover, pads with aluminum backing plates, and precise weight-reducing machining, the T2 is 50g lighter per brake (254g) than the Dominion A2.

You may be thinking, well does it still feel like a Dominion with all these weight savings? Absolutely. The T2 follows the Dominion family philosophy of a low-effort system with predictable, progressive ramp-up and a crisp bite point. This is achieved in part by a combination of an added glide ring on the master cylinder piston and sealed ball bearings at the lever blade pivot to reduce overall friction and provide a featherlight lever feel. To keep the feel consistent no matter the lever reach we have developed our Stable Rate Linkage (SRL) that delivers a consistent lever ratio regardless of lever position. This featherlight lever feel provides the rider with more intuitive control of their braking while simultaneously reducing arm fatigue when out on the trail. Many Dominion riders are surprised to learn that the cause of their arm pump is not always directly related to their suspension settings. By switching to Dominion their braking effort is significantly reduced and they can ride harder longer.

Each Dominion is factory set to have the lowest dead stroke possible providing precise engagement. As soon as you begin to move the lever, the pads start their journey towards the rotors. This provides the rider the ability to keep the levers close to the bars adding control to their ride. The bite point can be adjusted via a 2mm Allen key to keep the feel consistent between front and rear or to further tailor the feel of the brake to your preferences. The lever reach is also adjustable on the trail using a 2mm Allen key.

Reliability and serviceability were also top priorities in the design of the brake. We want our brakes to last and feel consistent throughout their life on your bike. By using metal pistons in the master cylinder and phenolic pistons in the caliper we can ensure that no matter the terrain or temperature your brake will continue to perform as consistently as it did on the first ride. This means that you will no longer have great rides sabotaged by wandering bite points or seizing pistons.

Servicing your Dominion is simplified through a few thoughtful design features. Our bleeding process utilizes a dual syringe process to easily push new fluid in and air bubbles out. Our 2-stroke dual-port bleed system adds an additional level of precision to your bleed process by allowing you to isolate your bleed to the caliper where air bubbles can hide behind pistons. When the time comes to rebuild your brake, the caliper is easily disassembled, and service parts are readily available. We have also tackled the annoying task of aligning your brake caliper when installing your brakes by adding our Crosshair Alignment screws on the caliper mounts. These small screws are a simple solution to an age-old issue by allowing you to adjust the caliper alignment in small increments during install and allow you to remove the caliper from the bike and reinstall it right back into the same spot.

The FEA-optimized modal shapes of our D-Series rotors are intentionally designed to oppose those of Semi-Met T106 and Sintered T100 pads, canceling out noise and vibration. The T2 utilizes aluminum backing plates on the standard Semi-Met T106 pads to further reduce weight. As with every Dominion pad, the T2 pads utilize our proprietary QuickBite² system for a fast and consistent burnish. Titanium rotor mounting bolts are included with every T2 Brake Kit for extra gram reduction.

Learn more at hayesbicycle.com

View replies to: Carbon Lever, Ti Hardware, and More Trickery Create the Limited Edition Dominion Brake

Comments